MGP grading with a machine

We talked about in-grade testing in the lesson: Structural grades and stress grades. These tests found that the traditional stress-rating system (based on strength groups and F grades) was not always accurate in predicting how full-length pieces of timber would perform in an actual structure.

The problem was a particular issue for radiata pine and some of the other plantation pines, since they’re far and away the most commonly used species in wall frames, roof trusses and other building applications.

Pines also tend to be knotty by nature, unlike most hardwoods, so it was never going to be an easy matter finding a universal strength-rating system that would suit all types of timber.

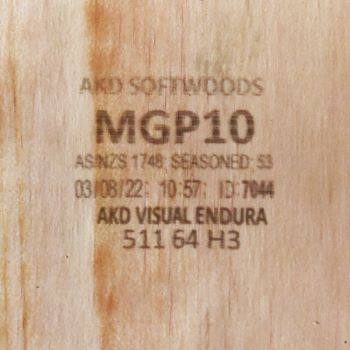

In order to overcome the problem with the pines, a new set of MGP (machine graded pine) grades was developed. The MGP system is based directly on the modulus of elasticity (MOE) of the timber. You’ll recall that we said in the last lesson – F-grading with a machine – that MOE is a measurement of stiffness, and the higher the MOE, the stiffer the timber is.

Basic MGP machines work like F-grading machines, since they still bend the board and measure its resistance to deflection. But instead of calculating an F grade via an assumed ‘modulus of rupture’ (MOR), they simply state the MOE category that the board falls into, as follows:

-

MGP 10 has a minimum MOE of 10,000 megapascals (MPa)

-

MGP 12 has a minimum MOE of 12,700 MPa

-

MGP 15 has a minimum MOE of 15,200 MPa

If you’re working with span tables or building plans that specify F grades, you may use MGP material in place of following F grades:

MGP 10 can replace F5

MGP 12 can replace F8

MGP 15 can replace F11

However, this doesn’t mean that the two grading systems are interchangeable. MGP material may be substituted for F graded material, but F graded material must not be used where MGP material has been specified.

The reason is that F grades were only ever designed to assess the ‘bending strength’ of a piece of timber, and any other properties – such as compressive, tensile and shear strength – are assumed to be more or less proportionate, based on the board’s grade. By contrast, MGP design tables cover a wide range of properties, and engineers have all of these attributes at their disposal when they’re making design calculations. So when a certain MGP grade is specified for a structural member, it could be based on factors other than simply its ‘safe working stress in bending’.

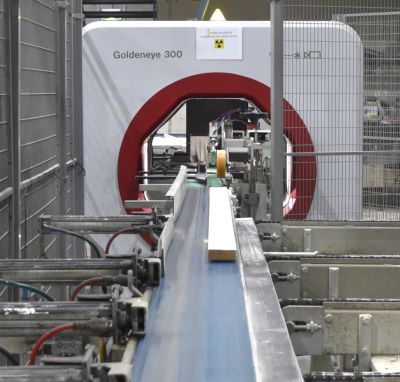

Scanners

Modern scanners no longer need to physically put a board under stress to measure its strength. They now use sonar and X-ray technology to analyse the timber, including its density and other growth characteristics. This information is processed by the scanner’s computer to calculate an MGP grade.

The boards are then fed into an ‘optimising' crosscut saw that automatically docks the boards to the preferred lengths entered into the computer program.