F grading with a machine

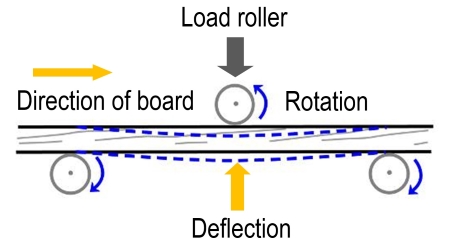

The load roller applies a force to the board, and bends it between two support rollers. The blue dotted line represents the deflection that occurs.

As the rollers rotate, the board moves through the machine, so that the deflection can be measured very quickly right along the length of the board.

Machine stress grading technology has evolved over the years, particularly for the plantation pines. Conventional machines still use the F grade system, and work by bending each stick of timber and measuring its resistance to deflection.

However, some of the pines are now generally graded under a different system called MGP (machine graded pine), and the machines that use the latest technology don’t need to bend the piece at all.

We’ll talk more about MGP in the next lesson. But for now, let’s concentrate on F grades. In order to understand how a machine stress grader calculates F grades, it’s important to know the difference between bending strength and bending stiffness.

Bending strength

The bending strength of a piece is derived from the point at which the piece breaks under a load, called the Modulus of Rupture (MOR), since this is the pressure required to actually rupture the fibres.

The F grade of the piece is based on the MOR divided by a safety factor. This is why the F grade is called the safe working stress in bending.

That is:

| F grade | = | modulus of rupture

(MOR) ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ safety factor |

= | safe working stress in bending |

Bending stiffness

By contrast, the bending stiffness of a piece is a measure of its Modulus of Elasticity (MOE). The higher the MOE, the less ‘elastic’ it will be – so the more resistant it is to deflection under a load.

That is:

| Stiffness | = | modulus of elasticity (MOE) | = | resistance to deflection |

Fortunately, there is a close relationship between MOR and MOE. If there wasn’t, the machine would have to break every piece to find its actual point of rupture before it could derive an F grade. But because the stiffness of the board is a good indication of how much stress it can take before the fibres rupture, the machine can measure the MOE by running the timber across two rollers spaced apart, and use a formula to work out the MOR and then the F grade.

In most boards, the grade will vary along the length, depending on the size and positioning of knots and other defects. So the machine sprays bursts of paint along the piece to mark the different grades, and uses the lowest one as the overall grade. This is sometimes shown on the end of the board in a long stripe of colour.

The colour codes used for the most common softwood F grades are:

| F4: | red |

| F5: | black |

| F7: | blue |

| F8: | green |

| Fll: | purple |