Structural grades and stress grades

Strength groups are a good starting point for working out how much stress a piece of timber can withstand, but they only give you a comparison between different timber species in terms of their relative strength.

In practice, individual pieces contain a variety of defects, such as knots, splits and gum pockets. Because the size and occurrence of these defects can have a serious effect on strength, each piece of timber needs to be assessed according to its structural grade.

There are two sets of structural grades – one for hardwoods and one for softwoods. In both cases, Structural grade No. 1 is the strongest, and each lower grade represents a 25% reduction in strength.

Each structural grade also has an F rating. F stands for force in megapascals (MPa). This is the amount of force a piece of timber can withstand without bending beyond an acceptable limit. A piece graded to F11, for example, will have a safe working stress in bending of 11 MPa. This is also called the stress grade of the piece.

The reason for having structural grades and as well as stress grades is that it allows a single set of grading rules to be used for a wide range of species, since:

-

structural grades categorise the allowable size and number of defects (for either hardwoods or softwoods, depending on which set of structural grades you are using)

-

stress grades (i.e. F grades) tell you how strong the piece is after allowance is made for those defects in the timber species from that particular strength group.

To understand this idea more clearly, have a look at the tables below. The first table shows comparisons in stress grades for four hardwood species and the second table shows similar comparisons for four softwoods. Notice that the denser species are comparatively stronger, so when the same sized defects in particular pieces from each species are given a Structural grade 1, their F grades vary depending on the relative strength of the species.

| Standard trade name | Air dried density (12% MC) | Strength group (seasoned) | Str. grade / F grade | |||

| 1 | 2 | 3 | 4 | |||

| Grey ironbark | 1090 | SD1 | F34 | F34 | F27 | F22 |

| Tallowwood | 990 | SD2 | F34 | F27 | F22 | F17 |

| Turpentine | 940 | SD3 | F27 | F22 | F17 | F14 |

| Alpine ash | 660 | SD4 | F22 | F17 | F14 | F11 |

| Standard trade name | Air dried density (12% MC) | Strength group | Str. grade / F grade | ||||

| 1 | 2 | 3 | 4 | 5 | |||

| Slash pine | 625 | SD5 | F14 | F14 | F11 | F8 | F7 |

| Douglas fir (Oregon) | 550 | SD5 | F11 | F11 | F8 | F7 | F5 |

| Radiata pine | 550 | SD6 | F8 | F8 | F7 | F5 | F4 |

| Western red cedar (USA) | 360 | SD8 | F8 | F7 | F5 | F4 | – |

Why do some of the F grades double up?

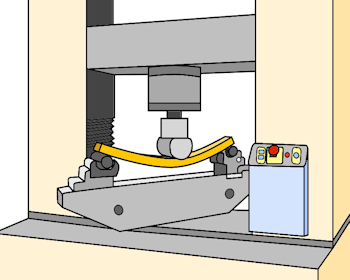

The traditional method for testing the strength of different species was to apply a load to small clear samples until they broke under the stress, and then record the force required to rupture the fibres. This was done with thousands of pieces in each species, and the results were averaged to derive a modulus of rupture (MOR).

The MOR was divided by a safety factor to find the safe working stress in bending for that species.

Then a further allowance was made for the various defects (or strength reducing characteristics) that occurred in individual pieces, providing a range of F grades to cater for different sized defects.

Although this system for determining stress grades has proven to be reasonably accurate over the years, it’s based on the assumption that small clear samples are a good indicator of how full-sized boards will perform when they’re put under a load. However, a more modern testing method called in-grade testing has found that not all species of timber behave in the way that the small clear samples predicted they would.

In-grade testing uses full-sized pieces of commercially available timber, and subjects them to the sorts of stresses they would need to withstand in an actual structure. Some species have had their original F grades re-confirmed, but others have needed to be revised.

One example of a species that has been revised over the years is radiata pine. The original set of F grades given to seasoned radiata pine, based on its strength group classification of SD6, were: F14, F11, F8, F7 and F5. The top grade (Structural grade 1) was subsequently revised down to F11, after further testing. More recently, it has been revised down again to F8, and the remaining grades have been set at: F8, F7, F5 and F4.

This means that Structural grades 1 and 2 both have the same F grade, and the full set of available grades now reads: F8, F8, F7, F5 and F4.

Not all species of timber have been tested using in-grade methods, so the Australian Standards now publish F grade tables that show method has been used to derive the results. Where in-grade results are available, these F grades take precedence over the original grade allocations that were based on strength group classifications.

Structural appearance grades

Structural appearance grades are used for timber that needs to comply with a designated F grade and also satisfy appearance requirements. Examples would be exposed beams or other load-bearing members that are in highly visible positions in a building.

In these cases, the same grading rules apply as for the normal Structural grades, but additional limitations are put on characteristics that detract from the appearance of the piece, such as loose knots, bark-encased knots, gum pockets or resin pockets, want or wane, and so on.