Measuring moisture content

The moisture content of wood is usually expressed as a percentage. This simply represents the weight of the water contained in the piece, compared with the weight of the woody substance itself.

That is:

| Moisture content (MC) % | = | weight of water ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ woody substance |

x | 100 |

The fraction part gives you the proportion of water to wood fibre, and multiplying it by 100 converts the fraction into a percentage.

For example:

A piece of softwood weighs 12 kg in its green state. The woody substance in the piece weighs 8 kg. What is the moisture content of the piece?

| MC | = | 12 - 8 ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ 8 |

x | 100 |

| = | 4 ⎯⎯⎯⎯⎯⎯⎯⎯⎯ 8 |

x | 100 | |

| = | 1 ⎯⎯⎯⎯⎯⎯⎯⎯⎯ 2 |

x | 100 | |

| = | 50 % |

In other words, the water in the piece weighs half as much as the wood fibres themselves.

Moisture and density

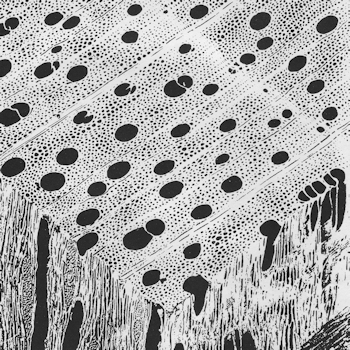

showing a fairly dense cell structure

(photo courtesy of CSIRO, used with permission)

The amount of moisture that a piece of wood can hold depends on its density, or the amount of solid wood fibre packed into a given volume.

For example, balsa is a very lightweight, porous timber which can hold up to 4 times its own weight in water. That is, in the growing tree it can have a moisture content of up to 400%.

On the other hand, ironbark has so much woody tissue with thick cell walls that there’s very little space left to hold water. Its green MC can be as low as 40%.

Methods of measurement

There are two main ways of measuring moisture content in timber. The simplest and most efficient method is to use a moisture meter. A more accurate process, used by kiln operators and others who need precise measurements, is the oven dry method.

Measuring moisture content with a moisture meter

being used to check the MC of timber floor boards

A moisture meter works by passing a current between two probes pushed into the wood, and measuring the electrical resistance between them. The principle is that dry wood is a good insulator and water is a good conductor, so the more moisture there is in the piece, the less resistance there will be to the electric current.

However, there are some factors that can make this reading inaccurate. These include:

the air temperature at the time

the species of timber being measured

the presence of any chemicals, such as preservative treatments.

You can improve the accuracy of the readings by looking up conversion tables which make corrections for these variables. But you need to remember that the result is only ever an approximation, probably within plus or minus 2%.

Measuring moisture content using the ‘oven dry’ method

to test moisture content in milled flooring

The first step in using the oven dry method is to cut a small test piece from the timber, making sure that you cut it away from the end so that it isn’t overly dry and unrepresentative of the rest of the piece. Then weigh the test piece on a set of scales. This will give you the total weight of the woody material and water combined.

Put the test piece in an oven at just over 100°C until all of the moisture has evaporated out of the cell cavities and walls. This process may take up to 24 hours.

Once the test piece has reached a moisture content of zero, weigh it again to find out what the woody material weighs is without any water in it. Then use the normal formula to calculate the moisture content of the original piece of timber.

That is:

| MC | = | weight of

water ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ weight of woody substance |

x | 100 |

| = | original weight - oven dry

weight ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ oven dry weight |

x | 100 |

For example:

A test piece is cut from a hardwood board. In its green state the test piece weighs 100 g. When it’s oven dry, it weighs 80 g. What is the moisture content of the original board?

| MC | = | 100 - 80 ⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯⎯ 80 |

x | 100 |

| = | 20 ⎯⎯⎯⎯⎯⎯⎯⎯⎯ 80 |

x | 100 | |

| = | 1 ⎯⎯⎯⎯⎯⎯⎯⎯⎯ 4 |

x | 100 | |

| = | 25 % |