Risk management

Risk management is all about identifying hazards and minimising the risk of them causing an illness or injury. The best way to identify hazards and decide on what action to take is to carry out a risk assessment.

There are three basic steps involved in carrying out a risk assessment:

identify the hazards

assess the risks

control the risks.

Identifying hazards

A hazard is anything that has the potential to cause harm. For timber workers, it includes things that might cause:

injuries or accidents – such as from saw blades, cutters, moving conveyor belts, forklift trucks, gantry cranes, steel strapping, flying particles, and so on

long-term health problems – such as excessive noise, airborne dust, repetitive strain on joints and muscles, radiation from the sun, and so on.

The most obvious way to identify hazards is to walk around the site and look for anything that could be unsafe. But there are other methods of finding potential hazards, such as talking to other workers, looking at injury records and reading the code of practice.

Below is a table of typical injuries suffered by production workers in the timber industry. It is a summarised compilation of information published by the Queensland Employee Injury Database: Injury statistics for wood and paper product manufacturing.

| No. | % total injuries | Body part | Injury type | Cause of injury |

| 1 | 29% | Hand and fingers | Lacerations and open wounds | Splinters; timber kick-backs; contact with saws and machinery; nail guns |

| 2 | 19% | Back | Muscle and tendon sprains and strains | Stacking, moving, lifting or carrying timber and panel products |

| 3 | 7% | Shoulder | Muscle and tendon sprains and strains | Stacking, moving, lifting or carrying timber and panel products |

| 4 | 5% | Eye | Sawdust, chips, splinters | Working with wood and machinery, airborne sawdust |

| 5 | 5% | Knee | Muscle and tendon sprains and strains | Stacking, moving, lifting or carrying timber and panel products |

| 6 | 5% | Wrist | Muscle and tendon sprains and strains | Feeding timber into machines; repetitive manual handling tasks |

| 7 | 3% | Ankle | Muscle and tendon sprains and strains | Stepping off forklifts or stacks of timber; tripping over objects |

| 8 | 3% | Foot and toes | Bruising, superficial crushing | Dropping timber or falling timber |

| 9 | 3% | Lower leg | Lacerations and open wounds | Walking into timber or pieces of metal; impact from metal objects |

| 10 | 3% | Abdomen and pelvis | Hernias | Stacking, moving, lifting or carrying timber and panel products |

| 11 | 3% | Forearm | Lacerations and open wounds | Working with or near strapping |

Assessing risks

Once the hazards have been identified, they should be assessed in terms of their likelihood to cause problems.

You’ll never be able to eliminate all hazards from the work environment, so you need to decide on how much effort should be put into dealing with each of the individual hazards that exist in the area you’re working in.

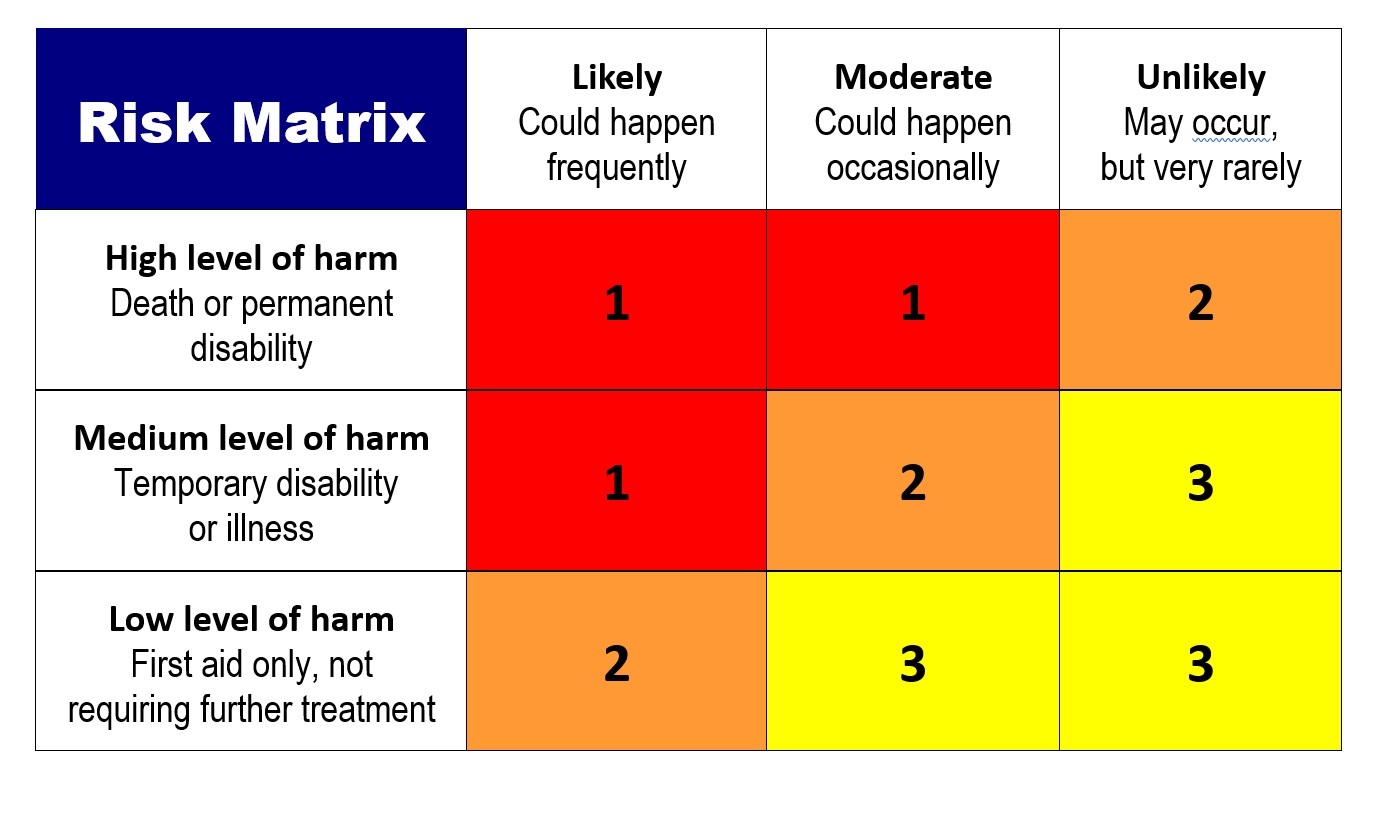

Below is a typical risk matrix used to rate the likelihood of an accident or incident occurring, and the seriousness of the harm that might result. This allows you to prioritise the hazards you’ve identified, so you can deal with the most serious ones first.

If you decide that a particular hazard has a risk rating of ‘1’, you should take immediate action to address the problem. Because of its level of seriousness, your only options are to either fix the problem on the spot, isolate the area or refer the issue to an authorised person.

If the hazard has a rating of ‘2’, you would still need to find a solution, but it wouldn’t have the same degree of urgency. In these cases, you would find an appropriate control measure (or combination of measures) to reduce or eliminate the risks and put the controls in place before you start work.

If the hazard is rated as ‘3’, you may decide to live with the risk, but take extra care or use some of the lower-level control measures listed below.

Note that there are different types of risk rating tables used by organisations for their risk assessments. The above example is a simple version adapted from a WorkCover risk matrix.

Controlling risks

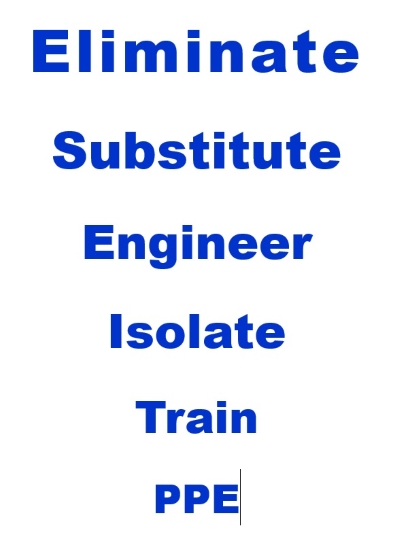

Most hazards can be controlled in a variety of ways. Obviously, the best control would be to eliminate it completely. But that isn’t always possible. So the most practical process for deciding on how to address a hazard is to find the best solutions from the hierarchy of controls.

It's called a ‘hierarchy’ because you start at the top of the list – removing the hazard completely – and work progressively down to the bottom, accepting that the hazard must remain and putting other measures in place to protect people from it.

Below is a brief description of each option in the hierarchy. In many instances, you may find that more than one control measure is needed to deal with the problem. For example, training and PPE are often used in conjunction with other control measures.

Eliminate the risk – such as through removing the dangerous machine or situation, or changing the way the job is done.

Substitute the process or hazardous product with a safer one – such as by using less hazardous machines or lower risk work practices.

Engineer a solution to control the risk – such as with guards, dust extraction systems or other mechanical aids.

Isolate the machine, process or area to keep workers and bystanders clear of the hazard – such as with the use of barriers or witches hats.

Train workers to avoid or manage the risks – such as through the use of Safe Operating Procedures, accreditations and regular refresher courses.

Issue personal protective equipment to workers – such as hearing protection, eye protection, safety boots, hard hats, high-vis clothing etc.

You can see that PPE is at the bottom of the hierarchy, because it doesn’t actually address the hazard itself – all it does is provide you with a level of protection when you’re directly exposed to the hazard.

Types of risk assessments

Risk assessment documents come in a variety of formats and levels of complexity. We’ve already discussed Safe Work Method Statements in the lesson Safe work procedures. But there are other forms of risk assessments that can be used for different purposes, such as when installing a new machine, changing the way a task is done or modifying the layout of a work area.