Engineered beams

There are many engineered wood products designed for structural building applications, such as beams, columns, floor joists and so on. Most of them are marketed under proprietary trade names. The various manufacturers publish their own design specifications and installation guides, which must be followed to satisfy the warranty conditions that apply to the product.

Some of the main categories are as follows. You’ll find more detailed information on the full range of engineered products on the Engineered Wood Products Association of Australasia website, along with a list of manufacturers that are members of the association.

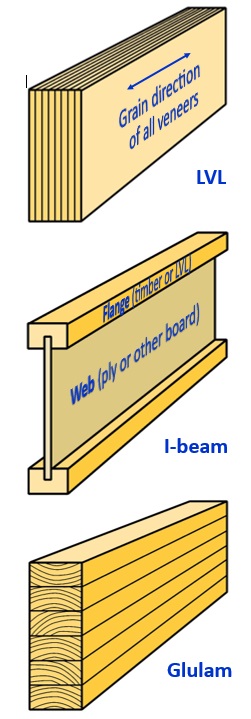

Laminated veneer lumber (LVL) is made from timber veneers glued together, with the grain of all veneers running lengthwise along the beam – unlike plywood, where the grain in every second layer runs at right angles to the layers either side. The parallel grain in all veneers improves the strength of the beam.

I-beams (also called I-joists) have a top and bottom flange with a panel in between that performs the function of a web. They are commonly used as floor joists when long spans are required, and are lighter and easier to handle on-site than solid timber of the same structural grade.

Glue-laminated timber (glulam) is made from solid pieces of timber laminated together. It is often used for columns and beams, and can be manufactured in curved shapes if required. High-grade glulam is also commonly used in kitchen and bathroom benchtops.