Plywood

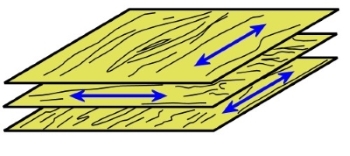

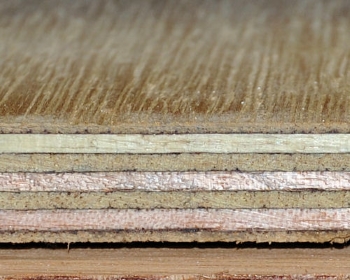

Plywood is made up of several ‘plies’, or layers of wood veneer, glued together and bonded in a high temperature press. The direction of the grain in each layer runs at right angles to the layer above and below it.

Because the face and back veneers have the grain running the same way, there is always an uneven number of layers.

There are two basic methods of cutting veneers:

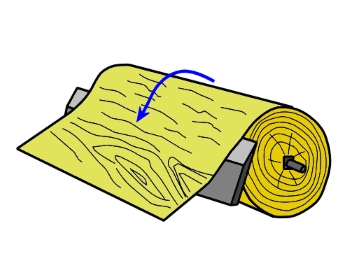

- Rotary cut veneer is peeled on a lathe. The veneer comes away in a long continuous sheet, which is re-cut into sizes suitable for laying up into plywood. Most plywood veneers are rotary cut.

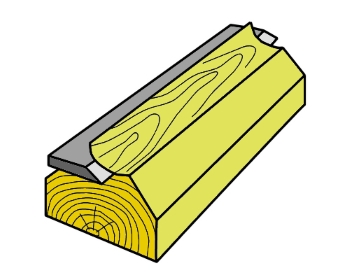

- Sliced veneer is cut from a ‘flitch’, or large section of timber, using a knife that slices across the grain. Although this process is more costly than peeling, it tends to produce a veneer with a more appealing ‘figure’ in the grain, so it is often used for high-grade decorative veneers.

Glue bonds and veneer grades

The glues used in plywood vary depending on the strength and durability required. They range from Type A, the strongest and most weather resistant bond, to Type D, the weakest and least durable bond.

Type A bonds are used in most plywoods these days, because the benefits generally outweigh the extra cost involved. However, Type C and D are sometimes still used in interior ply with light-coloured veneers that might be discoloured by the heavy brown Type A glues.

There are also four grades of veneer quality. These range from A Grade, which has a high quality appearance designed for clear finishing or staining, to D Grade, which contains various defects and is designed to be covered. Some manufacturers use the term S Grade to refer to a high quality sliced veneer.

Advantages

Plywood is very strong and very stable. This is because the alternating veneers maximise the natural strength of timber along its grain and minimise its tendency to shrink across the grain. It also allows the sheets to be nailed or screwed close to the edge without splitting. Panels that use Type A glue bonds have highly durable gluelines and suitable for use in wet areas.

Disadvantages

Because the layers of veneer are bonded at right angles to each other, there can be some tear-out on the edge if it is machined. The edge can also split when screws are used unless pilot holes are drilled first. Another disadvantage is its cost – plywood is more expensive than most other board products.